|

Y-M系列隔膜压力表

|

隔膜压力表采用间接测量结构,适用于测量粘度大、易结晶、腐蚀性大、温度较高的液体、气体或颗粒状固体介质的压力。隔离膜片有多种材料,以适应各种不同腐蚀性介质。

仪表适用于化学工业、化纤、合成纤维、石油、染化、制碱等工业。

Divide by indirect measurement of pressure gauges, to measure the viscosity, easy to crystallization, corrosive, high temperature of the liquid, gas or granular solid media pressure. There are many isolated patch material to meet the various aggressive media.

Instrument applies to the chemical industry, chemical fiber, synthetic fiber, oil, dyeing, caustic soda production, and other industries.

|

|

|

|

|

|

|

技术参数:

|

|

精确度:±1.6%,±2.5%

隔膜材料:OCr18Ni12Mo2(316),哈氏合金C(H276c),蒙乃尔合金(Cu30Ni70),钽合金(Ta),氟塑料(PTFE)

隔离器材料:耐酸不锈钢,含钼不锈钢,氟塑料。

密封垫圈材料:丁晴橡胶,氟塑料。

密封液:硅油、植物油、。

执行标准:JB/T8624-1997

Accuracy: ± 1.6%, ± 2.5%

Divide material: OCr18Ni12Mo2 (316), Harrington alloy C (H276c), Monel alloy (Cu30Ni70), tantalum alloys (Ta), fluorine plastics (PTFE)

Isolators material: Acid stainless steel, stainless steel containing molybdenum, fluorine plastics.

Sealing gasket material: Dingqing rubber, plastic fluoride.

Seal of: silicone oil, vegetable oil,.

Implementation of the standards: JB/T8624-1997

|

|

结构原理:

|

|

隔膜在被测介质压力作用下产生变形,密封液被压,形成一个相当于P的压力,传导至压力仪表,显示被测介质压力值。

温度影响:

因密封液的热膨胀及隔膜刚度与温度有关,在使用温度偏离20℃±5℃时,受温度影响有一个误差,其值为0.1%/℃。

Divide in measured media deformation under pressure, was sealed by pressure to form a pressure equivalent to the P, conduction to pressure instruments that measured media pressure value.

Temperature effects:

Sealed because of the lack of stiffness and thermal expansion and temperature, the use of temperature from 20 ℃ ± 5 ℃, the temperature impact on a error, its value is 0.1% / ℃.

|

|

液位差:

|

软管连接的隔膜压力表在安装时若受压部与压力仪表处不同位置,其液位差将形成一个压力差△P的影响,△P=密封液比重X液位差

Hose connected to divide the installation of pressure gauges, and if the pressure of the pressure on the instrument in different locations, its level will create a pressure differential △ P bad influence, △ P = sealed the proportion of poor X Level

|

|

耐蚀性:

|

隔膜压力表的耐蚀性能包含环境及测量介质的腐蚀特性,可按使用条件选配隔离器,隔膜,密封垫圈的材料。

Divide the corrosion resistance of pressure gauges includes the environment and the corrosion of media measurement, matching conditions can be isolated, divide, sealing gasket material.

|

|

|

|

|

测量上限

Mpa

|

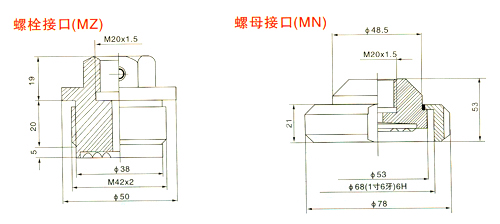

螺纹连接

|

|

D

|

C

|

M

|

|

0.1~0.4

|

118

|

25

|

20×1.5

(G3/8in)

(G1/2in)

(NPT1/2in)

|

|

0.6~16

|

87

|

25

|

|

25—40

|

92

|

27

|

|

|

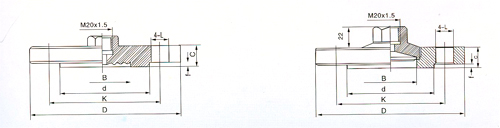

工型法兰:(MG)

|

测量上限

Mpa

|

管子通径

DN

|

法兰连接

|

螺孔

L

|

|

D

|

K

|

d

|

B

|

c

|

f

|

|

0.1~1.6

|

20

|

105

|

75

|

58

|

18

|

16

|

2

|

14

|

|

25

|

115

|

85

|

68

|

25

|

16

|

2

|

14

|

|

2.5~4

|

20

|

105

|

75

|

58

|

18

|

16

|

2

|

14

|

|

25

|

115

|

85

|

68

|

25

|

16

|

2

|

14

|

|

|

|

|

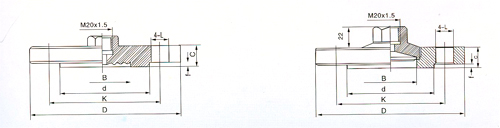

敞开式突面法兰(MF)

|

测量上限

Mpa

|

管子通径

|

法兰连接

|

螺孔

|

|

DN

|

D

|

K

|

d

|

B

|

C

|

f

|

L

|

|

0.16~1.6

|

32

|

140

|

100

|

78

|

31

|

16

|

2

|

18

|

|

40

|

150

|

110

|

88

|

38

|

16

|

3

|

18

|

|

50

|

165

|

125

|

102

|

49

|

18

|

3

|

18

|

|

2.5.4.0

|

32

|

140

|

100

|

78

|

31

|

18

|

2

|

18

|

|

40

|

150

|

110

|

88

|

38

|

18

|

3

|

18

|

|

50

|

165

|

125

|

102

|

49

|

20

|

3

|

18

|

|

6.3

|

32

|

155

|

110

|

78

|

31

|

24

|

2

|

22

|

|

40

|

170

|

125

|

88

|

37

|

24

|

3

|

22

|

|

50

|

180

|

135

|

102

|

47

|

26

|

3

|

22

|

|

10

|

32

|

155

|

110

|

78

|

31

|

24

|

2

|

22

|

|

40

|

170

|

125

|

88

|

37

|

26

|

3

|

22

|

|

50

|

195

|

145

|

102

|

45

|

28

|

3

|

26

|

可按化工部HG5019;HGJ45/54,一机部JB-81,国标GB911及日本JIS,美国ANSI等标准制造。

可按化工部HG5019;HGJ45/54,一机部JB-81,国标GB911及日本JIS,美国ANSI等标准制造。

|

|

|

|

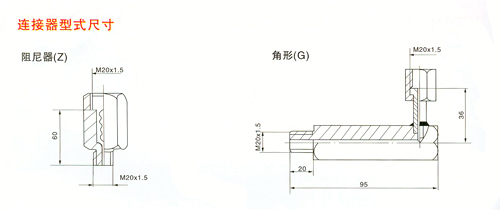

使用与订货须知:

|

仪表工作环境应无腐蚀性气体。

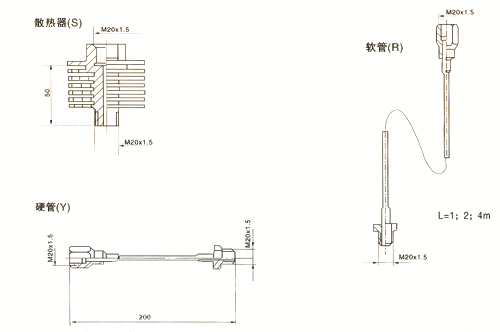

不得拆卸或更换已配置的仪表以免填充液外泄影响性能。订货请说明配置仪表名称、型号、测量上限、精确度及连接管型式、软管长、隔离器接口型式、隔离器接口材料、隔膜材料,以及法兰配接管子通径、标准代号等。如要求配置其它型式仪表,请另行详细说明。

我公司也可按用户要求定制进口设备配套隔膜压力表。

Instrument working environment should be no corrosive gas.

Shall not be demolished or replacement of the instruments have been configured so as not to affect performance filled with fluid leaks. Please indicate the allocation of orders Instrument name, model, surveying the ceiling, accuracy and type of connection, long hoses, interface type isolation, quarantine interface materials, lack of materials, and the flange to take over distribution of Path, standard code, etc. . If other type instrument configuration requirements, further details.

I also can be customized user requirements for imported equipment supporting divide pressure gauges.

|

|

|